| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | JHPD |

| Model Number : | BGFD |

| Certification : | RoHS, IATF16949 |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 10000 pcs per month |

| Delivery Time : | 20-30 days |

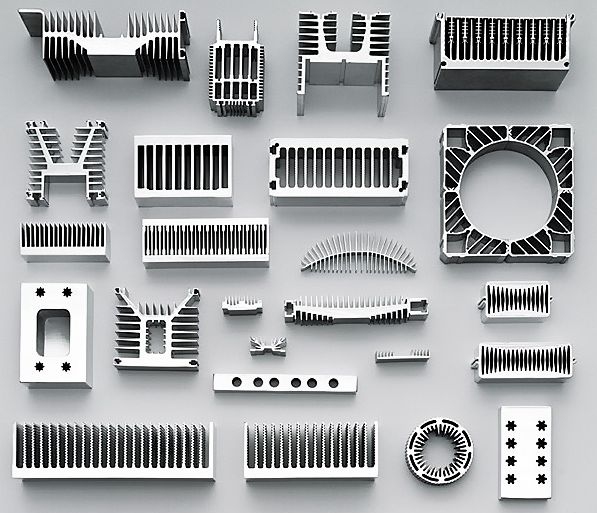

Extrusion Parts Heat Sink Windows And Doors Profiles Aluminum Profiles

Production description

| Place of Origin | Guangdong, China |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Part Process | Aluminum Extrusion |

| Model Number | Non-standard |

| Brand Name | JHPD |

| Drawing format | DWG,IGS,STEP,UG,PDF,Solidworks |

| OEM/ODM | Yes |

| Keyword | Heat sink Window profiles |

| Shape | Round or Customized |

| Extrusion Mold | one cavity |

Definition of aluminum extrusion process

Aluminum extrusion (or aluminum extrusion molding) is to put inside mold cavity (or container) of aluminium

billet powerful pressure, forcing directional plastic deformation in aluminum billet produced from the die hole

of extrusion die extrusion, to obtain the required cross section shape, size and has a certain mechanical properties

of parts or semi-finished plastic processing methods.

Advantages of aluminum extrusion process

1) Durable

One of the most notable advantages of aluminum is its resistance to decay, corrosion and weather. Aluminum

naturally rusts and resists corrosion without additional treatment. This is due to the presence of a thin, naturally

occurring protective film of alumina on the surface. By anodizing it, it becomes more resistant to corrosion.

For example, in the outdoor environment, 25 micron anodization can be carried out, which enhances both corrosion

resistance and surface finish. In addition, aluminum does not require maintenance and in most cases there is no need to

worry about corrosion.

2) Light and strong

Aluminum is more than 33% lighter by weight than steel, while retaining most of its strength. Most aluminium alloys have tensile strengths in the range of about 70 to 700 mpa and a density two thirds less than that of steel.

Product design engineers do not have to worry about the strength of aluminum extrusion parts, in the construction industry and the automobile industry can be used as structural parts, is the best substitute for other metal materials. The auto industry is making extensive use of aluminum alloys in order to make them lighter and reduce energy consumption.

3) Good thermal conductivity

Aluminum conducts heat much like copper, but weighs much less.

Aluminum is an excellent thermal conductor, and its extruded profile is designed to maximize thermal surface area and form hot channels. A typical example is a computer CPU radiator, where aluminum is used to take heat away from the CPU.

FAQ

1. How can I get the quotation?

Please send us the drawing, quantity, weight and material of the

product.

2. What kind of file can you read?

PDF, IGS, DWG, STEP,etc...

3. What is your way of packing?

Normally we pack goods according to customers' requirement.

For reference: wrapping paper, carton box, wooden case, pallet.

4. When can I get the samples and your main order time?

Payment : Tooling cost 50% deposit and 50% after T1 samples

approved .

Part cost :Net30

5. Where is the location of your company? Can we visit?

We are in Shenzhen, China. You are always welcome to visit us.

|