| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | JHPD |

| Model Number : | JHPD-03 |

| Certification : | ISO9001、IATF16949 |

| Price : | $0.5 - $1.0/ Piece |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 100000 Pieces per Month |

| Delivery Time : | A month |

Black Fireproofing SPI B1 ABS Plastic Injection Part Molding For Assembling

Custom plastic injection molded parts with high quality

1- Johnhalm provide high quality custom plastic injection molded

parts

2- Injection molded parts can be different material such as

ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect

3- Different injection molded parts can pass different

certififcation such as UL test, V0 fire resistant test,FDA

test,REACH test,SGS test and IP65

4- Johnhalm can also provide different surface treatment for injection molded

parts

5- Commonly use surface treatment for injection molded parts

as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI

6- Beside making injection molded parts,we also provide printing,welding,assembly and packing service

Quick Details

| Mold Standard | DME or HASCO |

| Mold Base | LKM,DME,HASCO,FUTABA |

| Cavity /Core steel | H13,S-7,S136,SS420,NAK80,P20 and other material as requirement |

| Hot Runner | Yudo |

| Cavity | Multi or single cavity |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Hydraulic cylinder | PARKER, TAIYO, STAUBU, JUFAN |

| Mold components | DME, Progressive, PCS, Punch, Royal, etc |

| Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| Surface Finish | SPI standard, VDI EDM, Texture, etc |

| Texture | Mold-tech, Yick Sang, Ni Hong ,Tanazawa etc |

| Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS,etc |

| Product weight | 5.0g~15kgs |

| Mould Life | 0.3 Million Shots- 1Million shots |

| Delivery Time | 4Weeks T1 samples , exact time depends on Mould Complexity |

| Packaging | Free-Fumigation Three-Plywood case for moulds, cartons for parts |

| Design software | CAD,UG, Pro E, Solidworks |

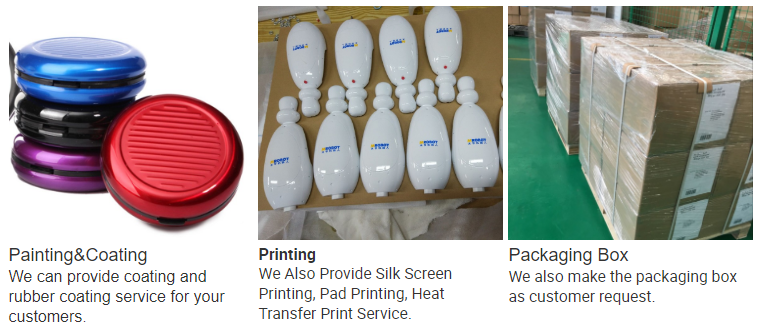

| Value-added service | Dust-free Spraying, Silk-screen Printing, Ultrasonic Welding, Thermal Bonding, Assembling, Prototype |

| Service area | Transparent, Over mold, double color, air assistant forming, deep barrel, Design R&D, Assembly |

| Our Capability | Auto, Aerospace, Household, Electrical, Industrial, Medial, Toys, Office, Cosmetic, Outdoor, OA Equipment etc |

Services

| 1 | Project Evaluation |

| 2 | Product Design |

| 3 | Electronic Design and Engineering |

| 4 | Mechanical Design and Engineering |

| 5 | Prototype Design and Engineering |

| 6 | Design for Manufacturing |

| 7 | Manufacturing Coordination |

| 8 | Mould design |

| 9 | Manufacturing |

| 10 | Second processing |

| 11 | Assembly and etc. |

| 12 | One-stop services for plastic parts. |

Production Information

1. Start from part design analysis

2. Mold design drawing and DFM report available so you can see how

is the mold going to be before mold making

3. If product is complex, mold flow report will be present as well

4. In house mold making shop ensure you mold quality under well

control.

5. Normally it takes 25-35 days to make mold,precise time depends

on part design

Product

|